Silicon Nitride Ceramic,Silicon Nitride Ceramic

Month: May 2019

ZrO2 Zirconia Ceramic Components

Zirconium oxide ceramics have the advantages of high hardness, good wear resistance, high toughness, low friction coefficient and good corrosion resistance. They are widely used in mechanical seals, ceramic balls, cutting tools, ceramic bearings, automotive engine parts, dewatering equipment etc. The wear resistance of zirconia ceramics is 15 times that of alumina ceramics. The friction coefficient of zirconia ceramics is only 1/2 of that of alumina ceramics, and the friction coefficient of alumina ceramics itself is very low. The density of zirconia ceramics is higher than alumina ceramics. The density of alumina ceramics is 3.5g/cm³, the density of zirconia ceramics is 6g/cm³, and the texture is finer. After grinding, the surface finish is higher, up to ▽9 or more. Mirror-like, extremely smooth, with a lower coefficient of friction.

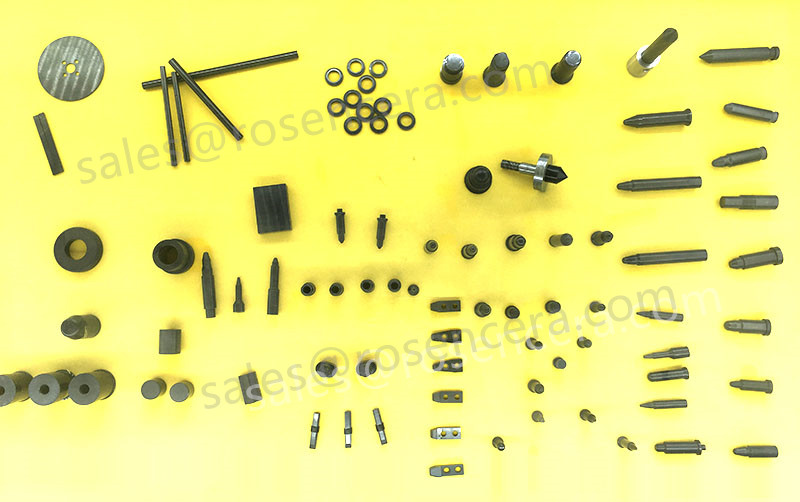

SI3N4 Silicon Nitride Ceramic Parts

Silicon nitride, the molecular formula is Si3N4, and the relative molecular mass is 140.28. The density is 3.22 g/cm³. Hardness HV1650. The melting point is 1900 ° C (under pressure). The thermal conductivity was 16.7 W/(m·K). Insoluble in water. Soluble in hydrofluoric acid. Oxidation starts at 1300~1400 °C in the air. The modulus of elasticity is 28420~46060MPa. The bending strength is 750-800 MPa. It can be prepared by heating silicon powder in nitrogen or reacting silicon halide with ammonia. It can be used as a high-temperature ceramic material and is an important structural ceramic material.

Silicon nitride ceramic material is a kind of super-hard substance, which has lubricity and good wear resistance. Besides hydrofluoric acid, it does not react with other inorganic acids, has strong corrosion resistance and resists oxidation at high temperatures. Moreover, it can resist the thermal shock, and is heated to above 1000 ° C in the air, and is rapidly cooled and then heated rapidly without breaking. Because of the excellent characteristics of silicon nitride ceramics, it is often used to manufacture mechanical components such as ceramic bearings, gas turbine blades, mechanical seal rings, and ceramic permanent molds. If a silicon nitride ceramic that is resistant to high temperatures and does not easily transfer heat is used to manufacture the heating surface of the engine component, not only the quality of the diesel engine can be improved, fuel is saved, but also thermal efficiency can be improved. The silicon nitride ceramic can be used as a gas turbine combustion chamber,silicon nitride mechanical seal ring (silicon nitride ceramic ring), an electromagnetic pump pipe (silicon nitride ceramic tube) for conveying aluminum liquid, ceramic valve, ceramic permanent mold, molten steel separation ring, and so on.

The characteristics of small friction coefficient of silicon nitride ceramic bearings are especially suitable for high temperature bearings. The working temperature can reach 1200 °C, which is 2.5 times higher than that of ordinary alloy bearings, and the working speed is 10 times that of ordinary bearings. The use of silicon nitride ceramics is very good for electrical insulation (insulating ceramics) and resistance to quenching and rapid heat. It can be used as a ceramic glow plug. It can be used to ignite the engine to shorten the engine starting time and start the car quickly in cold weather. . Silicon nitride ceramics also have good microwave permeability, dielectric properties and high temperature strength. They can be used as missile radomes for missiles and aircraft at six Mach or even seven Mach flight speeds. Silicon nitride ceramic materials have excellent thermal stability, high oxidation resistance and high dimensional accuracy. Since silicon nitride is a covalent compound with high bond strength and can form an oxide protective film in air, it also has good chemical stability. It is not oxidized below 1200 °C, and a protective film is formed at 1200 to 1600 °C to prevent further. It is oxidized and is not wetted or corroded by many kinds of molten metals or alloys such as aluminum, lead, tin, silver, brass, nickel, etc., but can be corroded by molten materials such as magnesium, nichrome, and stainless steel. Silicon nitride ceramic materials can be used in high temperature engineering parts, advanced refractory materials in the metallurgical industry, corrosion resistant parts and sealing parts in the chemical industry. Silicon nitride ceramics are very strong, especially hot pressed silicon nitride, which is one of the hardest substances in the world. It is extremely resistant to high temperatures, its strength can be maintained to a high temperature of 1200 °C without falling, it will not melt into a melt after heating, it will decompose until 1900 °C, and it has amazing chemical resistance and can withstand almost all inorganic acids. And less than 30% caustic soda solution can also resist the corrosion of many organic acids; at the same time it is a high-performance electrical insulation material.

Silicon nitride ceramics have excellent mechanical properties and processability, high temperature ceramics, corrosion resistant ceramics, wear resistant ceramics, magnetic ceramics, insulating ceramics and self-lubricating ceramics. Silicon ceramic bushings are widely used in magnetic drive pumps, chemical pumps, mortar pumps, mud pumps, piston pumps, etc.